Sponsored by:

Designing a Sustainable and Affordable Cooling Technology for Mattress

Cameron King, Dio Oey, Lakshmi Prerana Panchumarti, Elijah Tan., Thomas Thwaite, Wendi (Allen) Wu

Heat Index

Testing Procedure

Heat index (aka apparent temperature) is an adjustment of temperature based on the relationship between ambient temperature and humidity. You've probably heard of heat index before when getting the weather report. It tells you how hot air actually "feels" on peoples skin. Humidity is the driving variable in comfort. Heat index is tested by tracking temperature and humidity levels over time and running these values through a linear regression equation.

In this report, knit Tencel and Rayon were compared to a reference material, woven cotton. We used BME280 sensors to track temperature and humidity. Wired to an Arduino, the sensors run overnight initially logging data every minute for four hours to a microSD card. Four hours was chosen instead of eight hours due to time constraints. Two sets of tests were run - the sensor located at the feet of the sleeper not in contact with the body, and the sensor placed directly between the lower back and the mattress. The former is good for measuring heat index of the air under your sheets while the latter is good for measuring the heat index of the interface between your body and your mattress, which tends to be the hottest, sweatiest, and least comfortable.

Average heat index of the three fabric top layers. Note that each material maintained an upward trend. Average would be greater given longer test times.

Troubleshoot setup of heat index test. BME280 sensor reads to an Arduino which opens and writes the data to a text file on an SD card every minute for a given number of minutes. Parameters and functions are defined and written in the Arduino sketch code. The resulting text file is easily de-limited and plotted in excel.

Heat Index Test setup. After uploading the sketch to the Arduino, it can be unplugged from the computer and operate remotely given a power source. In this iteration, the sleeper lies directly on the sensor picture bottom center, in contact with the lower back. The material top layer of subject is pulled over the mattress and a cotton fitted sheet is put over that as would be the case with most mattress.

Redesigned heat index test with the sensor under the back. Most people have a cotton fitted sheet pulled over their mattress. This was interfering with the possible performance of our test materials. This test involves the subject laying directly on the Tencel, with the sensor under their lower back. Extra fabric is placed over the sensor to avoid direct moisture contact to curb oxidation.

Rothfusz regression equation used to calculate heat index

Results

First, lets look at the performance of the reference. Cotton is the most commonly used material for sheets and mattress toppers. During the "beneath the sleeper" test, the interface between sleeper and mattress quickly came to body temperature and remained there. Humidity rose to over 95% and heat index to over 160F. If this was the weather, you would be advised to stay indoors!

Now lets compare the performance of cotton to our proposed material, Tencel.

Tencel preformed amazingly better than cotton at mitigating humidity and therefore heat index. After just two hours (test was shorted by four hours due to time constraints) Tencel had a heat index 35 degrees cooler than cotton. Also notice the difference in humidity - 56% vs 77%. Also note the difference in slopes between Tencel and cotton. It takes longer for humidity and heat index to increase when using Tencel.

The choice of fabric top layer’s effect on heat index of the sleeper’s microclimate was found by tracking temperature and humidity every minute over four hours between the sleeper’s mattress and sheets. The heat index is found from the data points.

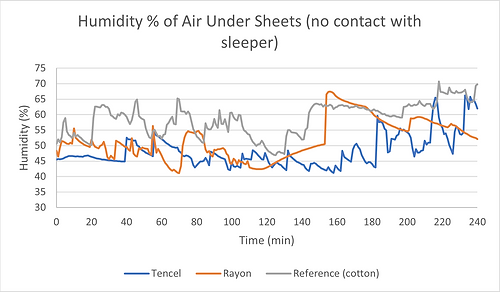

The humidity of the cotton peaked at 70.72%, Rayon at 67.45%, and Tencel at 65.55%. It is difficult to draw a conclusion from only humidity so temperature and finally heat index must be compared.

All tests began near the same temperature. Despite each material seeing a steady increase in microclimate temperature, Tencel maintained on average a lower temperature and ended the test slightly cooler. However, the relationship between humidity and temperature changes how the air feels on people’s skin. High humidity makes air feel hotter than it really is. Lowered humidity lowers the heat index and keeps the sleeper more comfortable. It is worth noting that initially, the air took longer to heat up when Tencel was used as a top layer.

Tencel performed better on average. Tencel maintained an average heat index of 85.2 F while rayon and cotton averaged 91.7 F and 92.0 F, respectively. Tencel seems to have outperformed rayon and cotton in controlling heat index. The six degrees temperature difference is not insignificant. This result can mostly be attributed to reduced temperature rather than humidity. There are no clear conclusions that can be drawn pertaining to the humidity mitigating benefits of Tencel with the data collected. More testing will be needed to make a solid claim. Considering the small sample size, the improvement in heat index shows promise.